When you hear 3D printing what do you think of?

Most people think 3D printing is a complex process that only computer savvy people are able to enjoy in science labs.

But 3D printing is as simple as layering and combining shapes on a computer to design any object you want.

After your design is finished, you simply send it to be printed, (just like you would send your En 102 paper, sheet music or vacation pictures), and it prints!

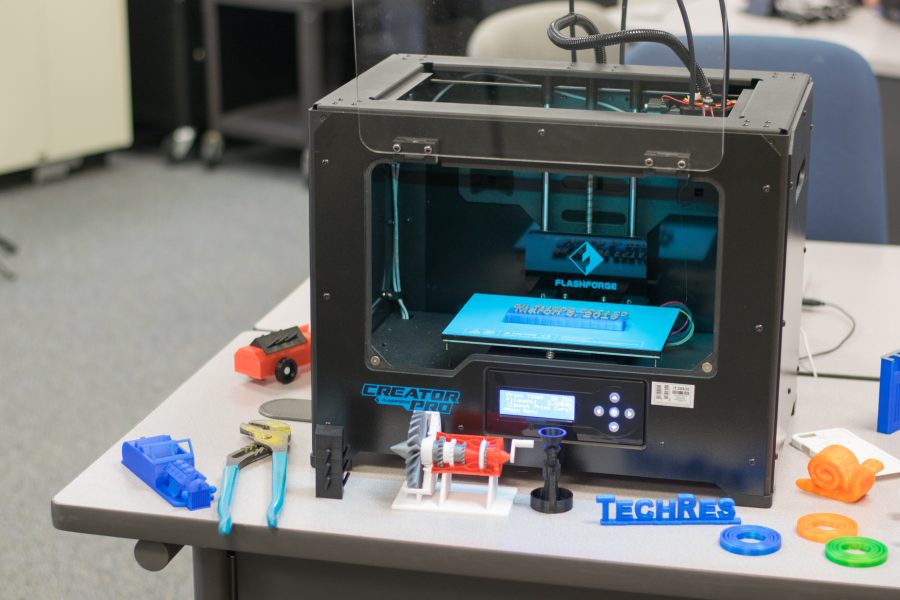

BJU owns two 3D printers, made available to students and faculty in the Alumni Building.

Matthew Gardenghi, senior manager of IT, said the Technology Resource Center’s goal is for the individuals at BJU to embrace their creativity as image bearers of the Creator.

One of the ways to manifest this creativity is through 3D printing.

“We got an idea: try to encourage students in a less classroom-oriented way to touch that concept of influencing the world instead of just being a consumer of the world,” Gardenghi said.

After attending a Gartner Symposium in Orlando, Florida, Gardenghi saw how passive society has become. When Gardenghi returned, he decided to start the 3D printing endeavor to call students into an active state of creating and living.

To encourage the students and faculty to use the 3D printer, anything people want printed is free.

Technology Resources is happy to pay the dollar it costs to print the average item because their primary focus is to foster a generation of creative individuals to better impact the world we live in.

Not only are prints free, but the computer software is user friendly, quick and easy to manipulate for simple or complex designs.

Brian Biggs and Melissa Paris, staff GAs, are up-to-date with the 3D printing software and can assist in bringing your designs to life.

You could also design something yourself and send it to Tech Resources and they will print it for you.

If you would rather design on your own computer, some software programs don’t even need to be downloaded to your computer.

“Tinkercad is a free web-based application [where] students don’t have to pay for anything,” Biggs said. “Instead, they log in with a username and email address and can access all their designs.”

The benefit of Tinkercad is the ability to access other users’ designs and save them to your own computer to print or bring them into your current design and customize them.

To assist students and faculty in maneuvering through the different software programs, Technology Resources will continue their workshops after Spring Break. The final two will be April 4 and April 11 at 7:15 p.m.

Last semester, a design-your-own Christmas ornament initiative was promoted across campus. So many students responded, Biggs said the 3D printer ran nonstop.

Because this event was such a success, Technology Resources purchased a second, more sophisticated printer.

Students will need to pay a small fee to print an item from the advanced printer, unless they can design the item themselves—then it remains free.

“We don’t want to be simply a service to print free things; we want to be a service to encourage and nurture the desire to build and grow and make things in the world,” Gardenghi said.

This semester, a 3D printing design contest will be held, and Dr. Pettit will decide the winner.

Students are to design a drink coaster and create a model of it using the 3D printer; the finalist’s coaster will be reprinted enough times to supply the administrative offices and conference rooms.

“[Drink coasters] are a simple and accessible form [with] room for creativity and variety. We also thought it would be something fun where we can have the student body giving something as a gift to [the] administration,” Biggs said.

Many students have found practical uses for the 3D printer—toys for nieces or nephews, key chains or numerous small gift items.

Others have applied the 3D printer to personal needs or their major.

Gideon White, freshman cross cultural services major, asked a friend in one of his classes if he could look into getting him a prosthetic hand.

White contacted Dr. Bill Lovegrove who directed him to Enabling the Future, an international website specifically for the designing of 3D printing prosthetics.

Each piece prints individually and is assembled using simple elastic string.

“I didn’t think it could be done until I saw it all come together,” White said. “I had it printed too small, so it didn’t work out for [my friend], but I can still give it to someone through this website who needs it.”

“Students should definitely take advantage of the opportunity,” White said.

What will you design?